Opening a conveyor belt sushi restaurant—also known as kaiten sushi—is no longer just about serving sushi efficiently. In today’s global market, success depends on automation strategy, food safety compliance, labor optimization, and experiential dining design.

1. Building a High-Profit Restaurant: Is the Rotary Sushi Model Right for You?

Before choosing layouts, consider if the sushi train model fits your goals. It performs best when:

- Located in prime areas or high-traffic zones.

In premium, high-rent areas, high overhead is a major challenge. However, the rotary sushi model turns this pressure into a profit engine.

First, the "instant dining" experience drastically shortens meal times. Guests eat and leave quickly, allowing a high turnover rate that generates enough revenue to easily offset expensive rents. Combined with a compact counter layout, every square inch of your floor plan is maximized to seat more customers than a traditional restaurant.

▲ Instant dining, faster turnover, lower rent-to-revenue ratio.

Furthermore, the continuous parade of colorful sushi acts as a powerful visual magnet, effectively enticing high-traffic passersby into making impulsive dining decisions. On the operational side, automation and self-service minimize the need for a large front-of-house staff, cutting down heavy labor costs. Finally, a steady stream of customers ensures fast food turnover, and with big data monitoring your waste, you can keep inventory lean. This transforms high rent costs into significant economies of scale.

- Facing hiring shortages or skyrocketing labor costs.

In an era of hiring crises and skyrocketing wages, the automated conveyor sushi model offers the perfect solution for restaurant resilience.

This model transforms traditional service into a "semi-self-service" powerhouse. By using conveyor belts or Shinkansen sushi trains to bring dishes directly to guests, you eliminate the need for runners. With self-service water faucets and tablets at every table, the frequency of manual service drops significantly, allowing a leaner staff to manage more tables with ease.

▲ Automation replaces manual delivery, significantly reducing labor costs and operational overhead.

In the kitchen, sushi robots and standardized prep methods mean "skill-free operations". You no longer need to rely on high-priced master chefs; even inexperienced staff can master the art of sushi in no time. Furthermore, integrated digital ordering and AI demand forecasting ensure your team works on what’s needed, reducing both labor strain and food waste. By shifting the focus from manual labor to tech-assisted efficiency, you can maintain high output with a smaller team. The savings can then be reinvested into competitive wages for your top talent, making this the ideal strategy for thriving in today’s labor market.

- Making dining "fun and shareable" through tech interactions to drive customer spending.

For owners looking to make their restaurant "fun and Instagrammable," rotary sushi transforms a simple meal into an exciting adventure for the senses.

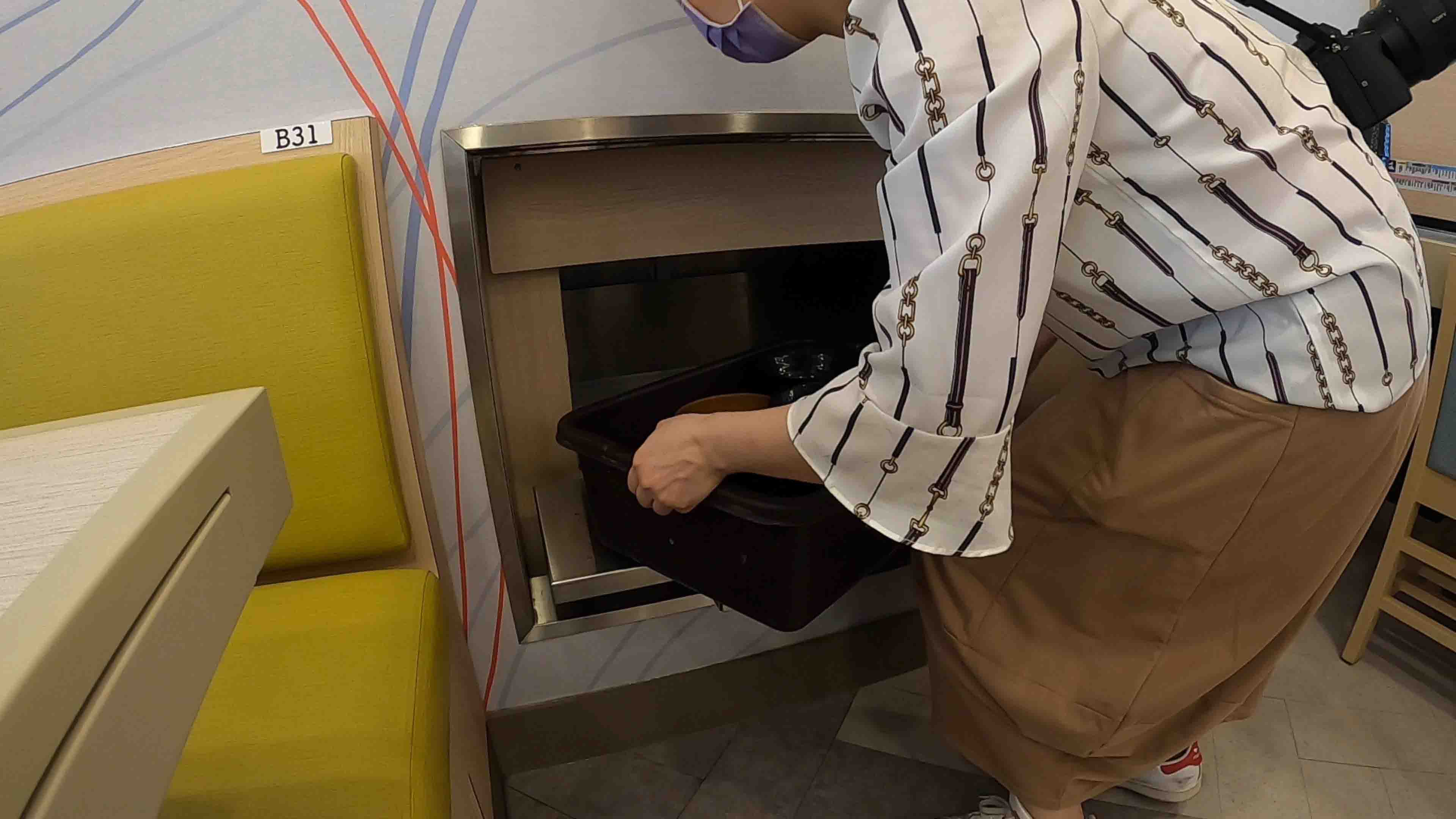

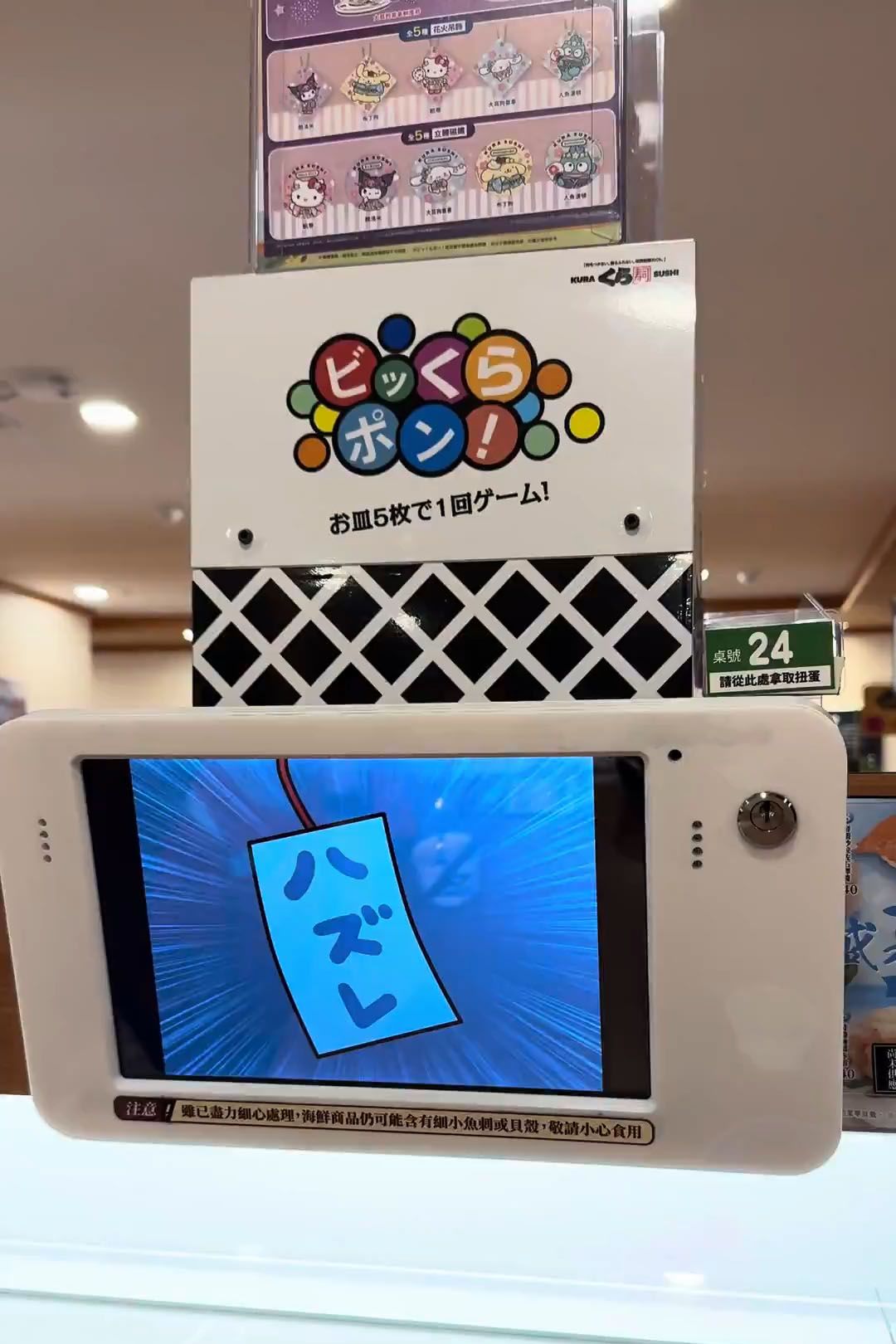

We’ve turned cleaning up into a game with our "Gachapon Game" (Plate-to-Toy System). By inserting used plates to trigger a lucky draw, guests feel a sense of achievement and are often tempted to order just a few more plates to play again. It turns the bill-paying moment into a delightful surprise. Meanwhile, the "Shinkansen sushi train" is the star of the show. Watching dishes zoom directly to the table like a mini bullet train creates a "theatrical" delivery experience that guests love to film and share on social media.

▲ Conveyor belt sushi embraces "Eatertainment," integrating gashapon games to fulfill customer desires for fun and interactive dining.

Combined with tablet ordering, guests can browse and choose at their own pace, making them the directors of their own dining experience. This blend of visual appeal and social shareability ensures your restaurant is more than just a place to eat—it’s a trendy hub of entertainment, tech-aesthetics, and social connection that keeps customers coming back for more.

2. Understanding Modern Sushi Train Business Models

Traditional Kaiten Sushi

The true magic of rotary sushi lies in the dynamic "feast for the eyes" it creates within the restaurant. First, the constantly moving sushi conveyor belt taps into the human instinct to track moving objects. A colorful parade of sushi plates acts as a continuous visual stimulant, effectively triggering appetite and distracting guests from any wait-time anxiety.

Secondly, this model offers the most intuitive product display possible. Guests don't have to guess what’s on the menu; they see the real deal—the glistening freshness, the marbling of the fish, and the generous portions—right in front of them. Seeing is craving, and physical presence is far more persuasive than text on a page. This direct visual appeal naturally encourages guests to order more, effectively driving higher sales for the restaurant.

▲ Dynamic Display: Capturing visual attention to trigger appetite and eliminate dining anxiety.

Despite its appeal, conveyor belt sushi also faces a significant challenge in terms of food waste, primarily for the following reasons:

- The Hidden Cost of Looking "Abundant":To keep the restaurant looking vibrant and fully stocked, the conveyor belt must maintain a high "fullness" to attract customers. However, the downside is clear: if customer traffic is slower than expected, the unsold dishes on the belt eventually exceed their freshness window and must be discarded. This waste, created just to maintain the visual appeal of a "busy" belt, is often a major hidden drain on a restaurant’s profits.

- Sushi has a short shelf life due to its freshness: As a raw food product, sushi is extremely sensitive to temperature and air exposure, with quality deteriorating rapidly as it circulates on the belt. To protect both food safety and brand reputation, dishes must adhere to a strict "freshness window" (typically 30-60 minutes). Once this window closes, items must be discarded—even if they still look perfectly fine. This unavoidable waste of ingredients represents a significant "cost black hole" that traditional rotary sushi models struggle to overcome.

- Visual selection preference: The hardest reality of the rotary model is customer psychology: guests will always wait for the "shining, fresh-out-of-the-kitchen" plate. Consequently, dishes that have circulated even a few times lose their visual edge and are immediately labeled as "not fresh" by discerning eyes. Once a plate has been passed over a few times, it becomes virtually invisible to customers, leading to a vicious cycle where it circulates endlessly until it must be discarded. This visual preference creates a significant waste burden that is nearly impossible to manage manually.

Shinkansen Sushi Train (Order-Only)

To overcome the challenge of traditional conveyor belts where food loses freshness as it circulates, the current mainstream solution is the "Shinkansen Sushi Train" point-to-point delivery system. Only after a guest orders via tablet does the kitchen prepare the dish fresh, which is then delivered with precision directly to their seat via high-speed tracks.

▲ Point-to-point Shinkansen sushi train delivery enables a made-to-order workflow, optimizing inventory and eliminating belt waste.

This workflow completely disrupts the traditional random-access model of rotary sushi. Since dishes no longer circulate aimlessly on a belt, the problem of food drying out or expiring—and the resulting need to discard it—is eliminated, bringing ingredient waste down to nearly zero. In US and European markets, where operating costs are high and food safety standards are exceptionally strict, the Shinkansen Sushi Train system, which guarantees freshness while significantly cutting costs, has already become the industry standard.

Hybrid Model (Traditional Kaiten Sushi + Shinkansen Sushi Train)

Modern restaurant configurations now favor a "Dual-Track" strategy: the lower level features a traditional conveyor belt to maintain a vibrant visual appeal and the convenience of grab-and-go dining, while the upper level utilizes high-speed Shinkansen sushi trains for precise, point-to-point delivery.

▲ Hybrid model (traditional kaiten sushi + Shinkansen sushi train) balancing ambiance with delivery precision.

This hybrid setup balances atmosphere with operational functionality. The conveyor belt creates a bustling visual feast that draws the eye, while the Shinkansen sushi trains handles made-to-order items or time-sensitive dishes (such as carbonated drinks, desserts, or premium nigiri), ensuring they reach the guest in peak condition. This dual-layer design not only caters to different dining preferences but also significantly boosts overall operational efficiency and service accuracy.

3. How Much Does It Cost? (ROI Timeline)

Initial Capital Expenditure (Startup Costs)

| Category | Item Details | Estimated Cost (USD) | % of Total |

|---|---|---|---|

| Hardware & Equipment | Kaiten Sushi/Shinkansen sushi train, robotics, cold storage | $92,000 – $177,000+ | 40% - 50% |

| Renovation & Tech | Digital ordering, POS integration, fit-out | $75,000 – $200,000 | 30% - 40% |

| Contingency | Deposits, initial inventory, marketing | $35,000 – $70,000 | 10% - 20% |

| Total | Estimated Total Investment | $250,000 – $500,000 | 100% |

▲ Initial capital expenditure (startup costs)

For a medium-sized facility (approximately 1,400–2,100 sq. ft.) located in a high-traffic commercial hub or shopping mall, the total investment typically ranges from $250,000 to $500,000.

1. Hardware & Equipment (40% - 50%):

- Food delivery equipment (Conveyor System, Sushi Train):A standard single-tier track costs between $50,000 and $80,000; a dual-tier system featuring a high-speed "Shinkansen sushi train" track starts at $110,000+.

- Sushi Robotics:Automated nigiri formers, rice washers, and maki cutters average $7,000–$17,000 per unit.

- Cold Storage:Specialized ultra-low temperature freezers for sashimi-grade seafood require an investment of $35,000–$50,000.

- Digital Ordering Systems:Integrated tablet-per-table setups with back-end synchronization cost approximately $17,000–$27,000.

- Interior Fit-out:Includes specialized plumbing, HVAC, and grease traps compliant with international food safety standards.

- Deposits & Initial Inventory:Approximately $35,000–$70,000 to secure the lease and procure premium initial stock.

Monthly Operating Cost Structure

The sushi train model follows a distinct financial profile: High COGS (Cost of Goods Sold) offset by Low Labor Costs.

- Cost of Goods Sold (COGS) 40% - 50%Higher than traditional dining to maintain ingredient quality.

- Labor Costs 20% - 25%Significant savings due to automation and semi-self-service.

- Rent & Utilities 15% - 20%Driven by premium locations and high-power refrigeration.

- Net Profit Margin 10% - 20%Success is highly dependent on high volume and turnover.

ROI & Payback Period

1. Revenue Projection:- To ensure profitability, the facility should target a Table Turnover Rate of 1.5 - 2.0 turns per hour during peak periods.

- Successful locations typically generate monthly gross revenues between $100,000 and $200,000.

- Optimized Model:With stable foot traffic and efficient waste management, the payback period is 18 to 24 months.

- Conservative Model:In emerging or lower-traffic zones, recovery may extend to 3 to 5 years.

Key Strategies to Maximize ROI

- Maximizing Space Productivity:Before a restaurant opens, spatial planning is the single most critical factor in determining profitability. An experienced delivery equipment manufacturer does more than sell hardware—they provide a blueprint for success based on years of proven results.

- Maximize Seating Capacity: While average suppliers might only suggest basic counter seating in leftover spaces, we specialize in intelligent layouts that maximize seat count within your footprint, directly increasing your revenue potential.

- Maximize Delivery Efficiency: By simulating delivery workflows, we ensure the smoothest operational flow, which significantly boosts turnover rates.

- Waste Mitigation:To eliminate the "hidden costs" of food waste, smart management is essential. By embedding IC Tracking Chips into each sushi plate, Hong Chiang give every dish a digital identity that can be monitored in real-time.The system analyzes peak-hour data to suggest the ideal mix of dishes on the belt and tracks the exact "time-on-belt" for every plate. If a dish exceeds its freshness window, the system automatically flags or removes it. With this digital freshness control, restaurants can keep their waste rates below 3%—or even lower. This doesn't just guarantee food safety; it directly recovers lost costs and converts them back into net profit.

- Eatertainment Value:Utilizing "Gashapon" toys or brand collaborations creates time-sensitive marketing buzz. By leveraging these "eatertainment" factors, operators can increase the Average Order Value (AOV) without adding to food costs—a strategy that has become one of the most talked-about marketing successes in the sushi industry in recent years.

Hong Chiang Taiwan offers clients "Free Floor Plan Consultation" and "Shinkansen Sushi Train Delivery Simulations". Before construction even begins, we help restaurant owners achieve two vital goals:

Choosing Hong Chiang means investing in a high-ROI profit system designed to squeeze the most value out of every square inch of your restaurant.

▲ The use of limited space with bar seating design.

▲ Leveraging IC chips for smart freshness tracking, precision-controlling food waste within 3%.

▲ Leverage "eatertainment" to drive higher Average Order Value (AOV) without increasing food cost burdens.