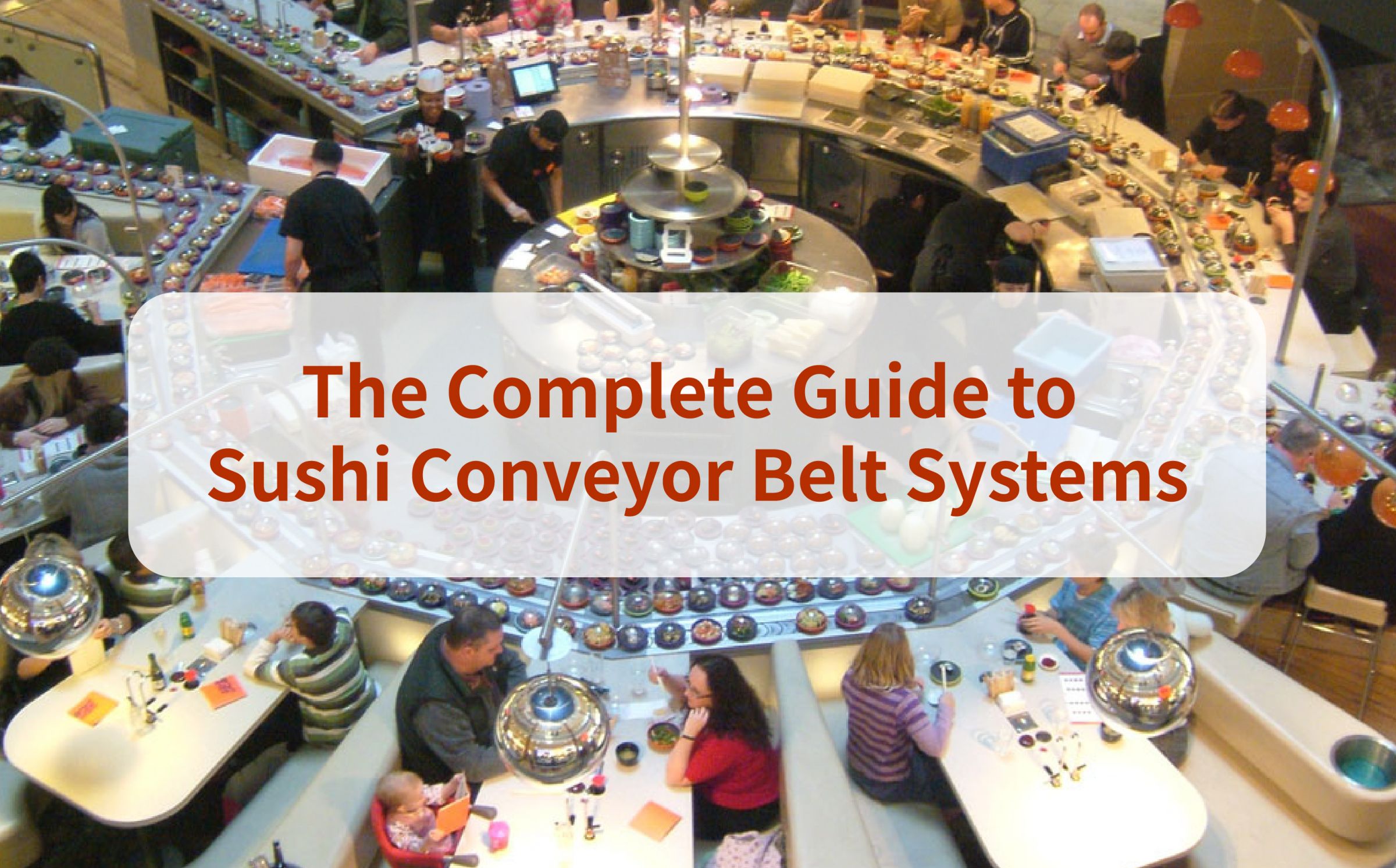

Sushi conveyor belt systems — also known as kaiten-zushi, conveyor sushi, or revolving sushi— have evolved far beyond being a novelty dining format. Today, a well-designed conveyor belt sushi system functions as a complete restaurant automation operating system, combining guest experience design, kitchen pacing, labor optimization, and data-driven compliance into one scalable infrastructure.

For modern operators and investors in North America and Europe, the conveyor is no longer a decorative centerpiece. It’s a strategic automation platform that can reduce front-of-house labor exposure, stabilize throughput during peak hours, and deliver measurable returns through sushi conveyor belt ROI improvement.

This guide provides a practical framework for planning, engineering, installing, and operating automated sushi restaurant systems— including hybrid automation sushi restaurant models that combine conveyors, express rails, and service robots.

1.Market Size & Global Growth Trends: Conveyor Sushi Market Growth in North America and Europe

The U.S. sushi restaurant industry generates over $30B annually, and conveyor sushi market growth is now one of the strongest automation-driven segments. Operators are increasingly choosing automated sushi restaurant concepts because they offer something traditional full-service restaurants struggle to provide in volatile labor markets: predictable throughput, stable staffing ratios, and consistent unit economics.

What started in coastal metros has expanded into suburban corridors and mid-size cities, where operators can often secure more stable rent structures and build loyal repeat customer bases. This expansion is also driven by changing diner behavior: guests increasingly seek experiences that feel fast, engaging, and self-directed—especially in formats that reduce waiting and service friction.

For global brands, the U.S. is also becoming a launch platform for international expansion. In many EU and cross-border projects, investors view automation not as a trend, but as infrastructure: a scalable operating model with long-term labor resilience.

▲ modern automated sushi conveyor belt system for scalable restaurant operations.

2.Pre-Opening Considerations: Sushi Conveyor System Planning Before You Sign a Lease

Before branding, interiors, or menu engineering, most high-performing projects answer three investment questions:

- Will a sushi conveyor system delay construction timelines?

- Can the conveyor sushi payback period realistically hit 18–36 months?

- Will restaurant automation strengthen or dilute hospitality?

Successful operators treat sushi conveyor system planning as part of the financial model—not a late-stage equipment add-on. That means aligning system selection with staffing assumptions, guest flow, kitchen production pacing, and compliance requirements from day one.

When automation is engineered into the concept early, the project avoids costly change orders, reduces “dark rent” exposure, and opens with a stable operational rhythm. In practice, the most profitable conveyor restaurants are the ones that treat ROI and engineering as part of the brand DNA.

3.Core Technical Decisions: Sushi Conveyor System Design That Protects Profitability

Every successful sushi conveyor system design begins with a few engineering decisions that determine long-term efficiency:

- (A) Guest & Staff Flow (Layout Engineering)

A restaurant automation system only creates value when it reduces congestion and repetitive motion. Layout must separate guest circulation from staff restocking routes to prevent cross-traffic, collisions, and service slowdown.

- (B) Measurable Labor Efficiency

Operators should be able to quantify labor reduction, not just “feel” it. The goal is to remove repetitive delivery tasks so staff can shift toward higher-value hospitality, quality control, and upselling.

- (C)Kitchen Integration & Production Pacing

If kitchen production doesn’t match belt speed, plates stack up or move too slowly—breaking the dining rhythm and damaging guest experience. These misalignments are expensive to fix post-opening and rarely restore full efficiency.

A disciplined approach to conveyor sushi engineering isn’t “technical detail.” It’s the foundation of scalable margins.

▲ sushi conveyor system design for labor efficiency and kitchen integration.

4.ROI Fundamentals: Sushi Conveyor Belt ROI, Payback Period, and Unit Economics

- Labor & Operating EfficiencyIn many North American restaurants, labor can consume 30–35% of total revenue. A well-executed conveyor or hybrid model can compress that ratio to ~20–25%, often reducing front-of-house staffing needs by 30–40% without lowering service quality. This isn’t just payroll cutting—it’s workflow restructuring. When automation handles repetitive delivery/retrieval, staff can focus on guest guidance, upselling, cleanliness consistency, and premium experience cues.

- Throughput & Table TurnoverConveyor dining reduces the time gap between seating and serving. During peak windows, this can lift table turnover by 15–20%, increasing covers per shift without increasing floor area.

- Visual Sales & Check UpliftContinuous motion and visible abundance encourage impulse selection. Many operators see average checks rise 10–15%, especially when combined with digital ordering, limited-time items, and premium drops delivered via express rails.

- Hidden Costs: Training & TurnoverAutomation also reduces training load. In high-churn markets, the cost of recruiting and retraining is a silent margin killer. An automated delivery backbone lowers the learning curve, making operations more resilient.

5.Experience Design: Low-Pressure Dining Automation and Why Guests Prefer It

Modern diners increasingly evaluate restaurants by control and pace—not only flavor. People want to start faster, avoid waiting, and reduce social friction. This is why low-pressure dining automation has surged post-pandemic.

Conveyor sushi naturally fits this shift. The steady motion of plates and real-time choice create a participatory experience that feels self-directed rather than transactional. Guests aren’t waiting for service—they’re part of the service.

For operators, this is brand differentiation. A well-designed conveyor doesn’t replace hospitality; it changes where hospitality lives—staff focus shifts from running food to guiding choices, maintaining standards, and elevating premium items.

▲ low pressure dining automation conveyor sushi experience.

6.Typical Project Workflow: Sushi Conveyor Installation Process That Prevents Delays

In U.S. and EU projects, every week of delay can mean tens of thousands in rent and lost revenue. That’s why a structured sushi conveyor installation process matters.

- Phase 1: Site Assessment & Flow Optimization

Evaluate electrical capacity, plumbing, structural constraints, and service routes. Use 3D modeling to simulate guest/staff paths and maximize RevPASH.

- Phase 2: System Integration Planning

Align conveyor with POS, interior constraints, kitchen utilities, dishwashing return, and service approach. Early integration prevents change orders.

- Phase 3: Pre-Wiring & Utility Alignment

Modern systems often include diagnostics and monitoring. Embed required circuits and data ports during construction—especially for UL / NSF / CE compliance.

- Phase 4: Modular Installation

Prefabricated components can shorten build timelines by 30–50% and reduce dark-rent exposure.

- Phase 5: Performance Testing & Calibration

Stress-test stopping precision, delivery timing, and RFID plate accuracy. Small calibration errors can cause major operational friction.

- Phase 6: Staff Training & Soft Opening

Train daily maintenance routines, alert response, and operational adjustments. Use soft opening to tune delivery cadence and throughput targets.

7. Hybrid Automation: The Triple-Path Delivery Ecosystem for Scalable Efficiency

A single delivery method introduces risk—peak loads, downtime, or layout limitations can disrupt service. This is why top operators adopt a hybrid automation sushi restaurant model: multiple delivery paths that balance speed, visual sales, and coverage.

- The Triple-Path Delivery Ecosystem

- 1.Rotary Conveyors for Impulse Discovery

Best for high-velocity standardized items; drives visual sales and check uplift.

- 2.Express Rails for Custom Orders

High-speed table delivery for made-to-order and premium items; reduces FOH traffic and improves consistency.

- 3.Autonomous Service Robots for Flex Coverage

Ideal for private rooms, corners, or areas tracks can’t reach—without expensive structural renovation.

- 1.Rotary Conveyors for Impulse Discovery

- Back-of-House Integration & Utility Design

True ROI comes from lifecycle integration: plate return workflows, dishwashing efficiency, and beverage automation. Integrated systems can reduce waste and stabilize daily performance.

- Data-Driven Waste Reduction & Compliance

RFID tracking supports freshness management and production feedback loops. Operators can identify stalls, optimize menu pacing, and reduce waste dramatically when analytics are used correctly.

- Search terms this section targets:

- hybrid automation sushi restaurant

- conveyor and robot integration restaurant

- express rail sushi delivery system

- RFID conveyor sushi system

8.Risk Management & Operational Stability: Designing for Resilience, Not Just Performance

Even the best conveyor systems face risks: mechanical downtime, sanitation workload, RFID errors, production mismatch, and in premium environments, noise/vibration issues. Overseas parts lead times can also create operational exposure.

The solution is restaurant automation risk management through resilience-by-design:

- Redundant motors or modular replaceable components

- Preventive maintenance schedules tied to KPIs

- Cloud diagnostics for early detection

- Local service partnerships for response speed

- Hybrid delivery architecture to keep service running during repairs

What separates high-performing conveyor restaurants from struggling ones is not “having tech.” It’s having operational discipline and contingency planning.

▲ conveyor sushi downtime prevention and operational resilience.

9.Maintenance & KPI: Make Sushi Conveyor Maintenance KPIs a Financial Control System

Preventive maintenance is a financial strategy, not a technical afterthought. Emergency service for commercial equipment can be expensive—and downtime carries hidden costs through lost covers and damaged guest experience.

Smart operators track sushi conveyor maintenance KPIs that connect equipment reliability to profit:

- Downtime per week (target: < 30 min)

- Checkout exception rate (target: < 5%)

- Plate waste rate (target: < 15%)

- Peak throughput growth (target: +15–20%)

These KPIs are business levers. Small increases in waste or downtime can erode monthly margins fast. When metrics are visible and acted on, the automation becomes not just reliable—but bankable.

Search terms this section targets:

10.Regulatory & Compliance: UL, NSF, and CE Certified Sushi Conveyor Systems

Food safety and electrical compliance must be engineered from the beginning. In the U.S. and Europe, conveyor sushi systems often need alignment with overlapping standards such as UL, NSF, and CE depending on market and components.

Choosing UL NSF CE certified sushi conveyor equipment reduces approval risk and prevents costly redesigns after inspections—especially when non-compliant imports force changes to electrical load design or sanitation specs.

For international developers, compliance is often the #1 reason projects stall. Compliance-by-design workflows—coordinating early with architects, engineers, and suppliers—reduce delays, lower inspection friction, and increase predictability for multi-market expansion.

▲ UL NSF CE certified sushi conveyor system compliance.

Conclusion

Conveyor sushi systems have moved far beyond being simple dining novelties—they’re now infrastructure platforms for the modern restaurant industry. By combining automation, data intelligence, hybrid fulfillment, and experience design, these systems turn motion into measurable business value.

When implemented strategically, automation doesn’t just streamline operations—it rewires the economics of hospitality. It stabilizes margins in a volatile labor market, delivers predictable ROI, and builds a scalable foundation for multi-market expansion.

In this new era of restaurant design, the conveyor isn’t decoration. It’s the engine of efficiency, the bridge between guest experience and operational discipline. The restaurants that master this balance will not only survive the next decade of disruption—they’ll define it.

Ready to Modernize Your Restaurant? Our engineering team specializes in certified conveyor systems for the North American and European markets.

FAQ

- Q1: What is the typical sushi conveyor belt ROI and payback period?

A: Many well-managed projects achieve sushi conveyor belt ROI payback in 18–36 months, driven by labor reduction, throughput gains, and check uplift.

- Q2: Can sushi conveyor systems fit small or irregular restaurant layouts?

A: Yes. Modular tracks and hybrid automation support narrow footprints, corner units, and L-shaped spaces.

- Q3: Do automated sushi restaurant systems feel too mechanical for guests?

A: Often the opposite—automation enables low-pressure dining by reducing waiting and giving guests more control.

- Q4: What utilities are required for a conveyor belt sushi system?

A: Requirements vary but often include dedicated circuits, data ports, and proper plumbing alignment depending on the full automation ecosystem.

- Q5: How do RFID conveyor sushi systems reduce food waste and ensure freshness?

A: RFID tracks dwell time and alerts staff to remove items that exceed freshness limits; analytics improve production pacing and reduce waste.

- Q6: What happens if the system needs maintenance—does the restaurant close?

A: Not necessarily. Hybrid architectures can keep service running by shifting orders to alternate delivery paths.

- Q7: Are these systems UL / NSF / CE compliant in the U.S. and EU?

A: Reputable suppliers offer UL / NSF / CE aligned solutions; compliance should be verified early to prevent redesign and delays.